Week 7

Hello Peers,

Final week is here and below is my submission.

I have answered all questions but just changed the sequence so that you get a better understanding of the evolution:

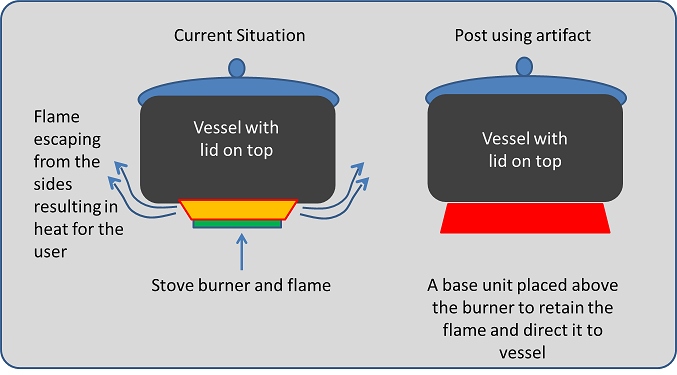

3. Background & the Gap

"In what way might I reduce heat around the stove area for a more enjoyable cooking process"

I love to cook. However one of the most difficult aspects of cooking (and more so with indian cooking) is the heat around the cooking stove. It gets hot and sweaty and exhausts only manage 30-50% of the heat but the rest is still quite bad – especially given the humid climate. A mechanism to reduce/manage this heat would make the cooking process more enjoyable.

Key user Needs:

- Retain heat better within stove area

- Don’t let excess heat energy get wasted by escaping around the vessel

- Isolate user from heat

Reference of Alpha prototype from week 6

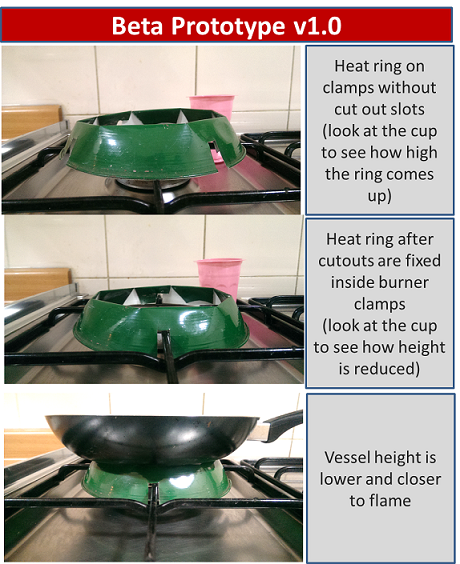

The two key refinements identified were

- Provide slots on the side to ensure that artifact fits on the burner clamps and the vessel was closer to the flame

- Better material of artifact to better retain heat and isolate user

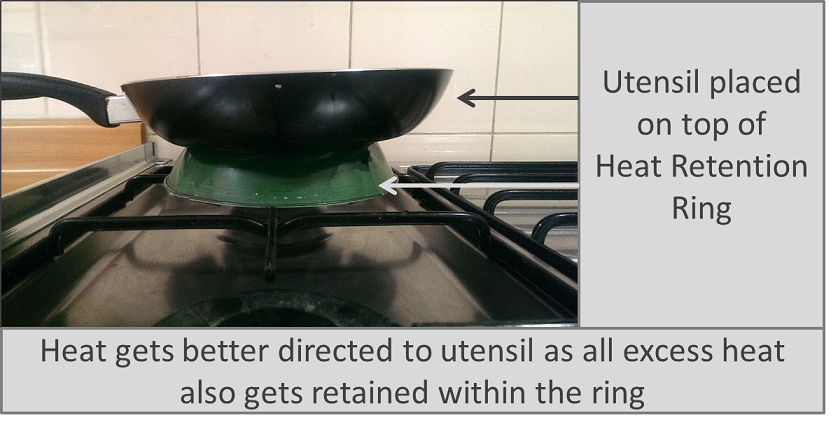

2. Nice Images of prototype

Beta with refinement made to alpha (incorporate refinement 1 above)

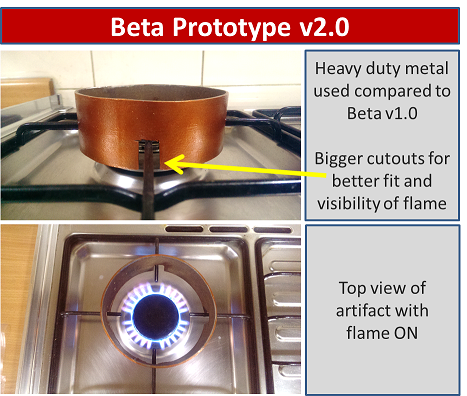

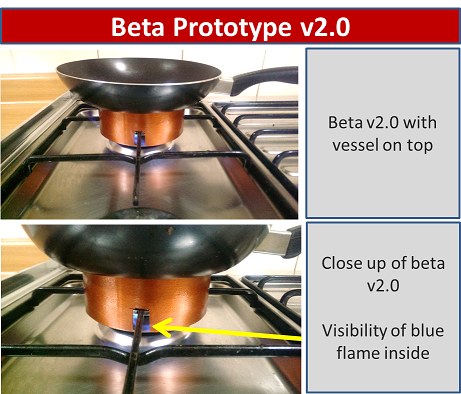

Beta V2

More shine, more gloss and overall attempt to make the beta look and feel nice

More Heavy duty metal used for better retention of heat (incorporate refinement 1 & 2 from alpha)

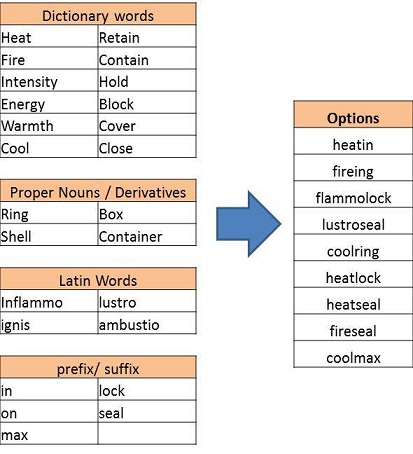

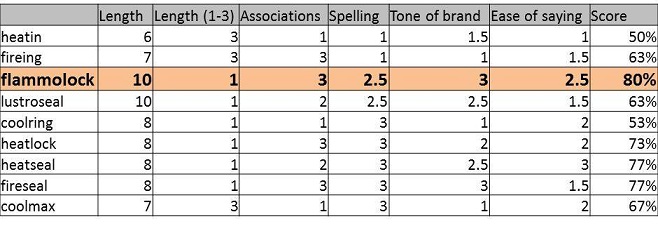

1. Name for Artifact

4. Further Refinements

One of the further refinement ideas was to provide visibility to the flame when the artifact is places on the burner. For this I am evaluating heat resistant glass. I found a heat resistant glass bowl in the market but when I tried to cut it into a ring it shattered. I have been unable to find a glass cutting workshop where I would be able to get this created.

This would be the final stage of refinement for this artifact.

5. Any other information

Doing my best ….

a. Given that the gap that I was trying to address involved fire, I had to be extremely careful. This imposed many limitations to try out things during initial ideation stages since I couldn’t put a cardboard prototype on the burner and test it. Hence a lot was upto imagination / simulation

Learning: when developing products with such constraints always budget for additional time for better evaluations (cannot work on the weekly schedule like for our course)

b. I have recently moved to a new city & country. Finding some of the basic material for making the prototype was extremely tough since I did not know the right places to go or right workshops etc.

Learning: Important to build list of resources for your areas of work for smooth execution

I have tried to put up my best given these constraints.

Hope you like the project.